Rethinking Arrow and Broadhead Performance

A NEW Series of Bowhunting Articles by the Ashby Bowhunting Foundation

Article 9: Factor 8 – Shaft Profile

Would you like to hunt with arrows and broadheads that give you pass-throughs on big game shot after shot? Would you like to have complete confidence in your arrows and broadheads to give you lethal penetration and reliable kills even if you hit bone? Of course, you would! Every serious bowhunter wants that kind of performance from their setup. Join us for Dr. Ed Ashby’s Top 12 Penetration Enhancement Factors.

After extensive testing, Dr. Ed Ashby identified twelve specific arrow penetration enhancement factors. He then ranked them in order of importance so that bowhunters would have a straightforward guide as to what they should build into their arrow and broadhead setups—and in what order—so they could create the most reliable and lethal setups possible.

To optimize your arrow and broadhead builds, it is recommended that you incorporate as many of the 12 Penetration Enhancement Factors as possible.

The eighth factor, shaft profile, will be discussed today.

“On all shots, tapered shafts show an 8 percent penetration gain over parallel shafts and a 15 percent gain over barrel tapered shafts.” – Dr. Ed Ashby

The profile of an arrow shaft is not a subject that seems to come up in discussion often, but that does not mean it should be overlooked. The profile of an arrow shaft can have a multitude of different effects—some of which can have a direct impact on the level of penetration achieved. Overall durability, inherent FOC, how and where the shaft flex, as well as the drag experienced in flight and penetration all have ties to the profile of the shaft.

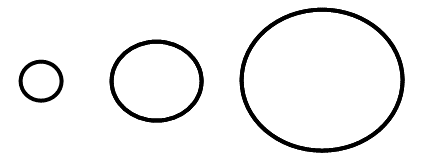

Before we get too far though, what does shaft profile even mean? The profile of a shaft describes how the shaft looks from a two-dimensional perspective when comparing the top and bottom edges. If you take one of your shafts and lay it against a contrasting background, you can see its profile. How does the top edge look in reference to the bottom edge?

Do the edges appear to be the same distance apart? As you may have guessed, this would be considered a parallel shaft. The outer diameter is consistent all the way through, from tip to tail. The vast majority of shafts available follow this design as it’s the easiest to make.

Do the edges appear to slowly get further apart? When the edges of a shaft are angled in this manner it is considered a continuous taper or simply a tapered shaft. The outer diameter will consistently increase as you move from one end to the other. Typically, the larger end of a tapered shaft will be the front. While they not as common in the modern market, there are a handful of carbon tapered shafts available such as the Grizzlystik TDT, Easton T64, and multiple shafts from Arrow Dynamics. To our knowledge, only the Grizzlystik TDT offers a true continuous taper (tip to tail). The others are more of a hybrid taper that have a section of larger diameter parallel shaft at the front which then transitions to a tapered rear which gets smaller. Looking at the more traditional side of things, tapered shafts are still fairly common and can be acquired in a multitude of woods.

Do the edges appear to curve with the largest section in the middle? This somewhat football shaped profile is considered a barrel taper. The middle of the shaft is the largest diameter and it tapers down, decreasing in diameter as you move towards both ends. This profile is not very common anymore, but can still be seen with some traditional wood shafts and some target shafts.

So how do these different shaft profiles impact durability, FOC, flex, and drag? Let’s look at each element individually to break it down.

Overall Strength & Durability

When looking at tubular strength, the outer diameter plays a big role. The larger the outer diameter of a tube, the more surface area it has for distributing any forces applied to it—resulting in a higher force being required to cause tube failure. Our modern arrow shafts are simply carbon tubes, so the same rules apply.

A “standard diameter” shaft (0.245” inner diameter) will naturally be able to withstand more force than a “small diameter” shaft (0.204” inner diameter) with the same wall thickness. A “micro diameter” shaft (0.165”) will require even less force than the “small diameter” shaft. Notice that I mentioned when wall thickness is equal in the previous statement. This is because following our standardized shaft “sizes,” the thicker the walls, the larger the outer diameter of the shaft will be. The outer diameter is the predominant factor as it determines how much area is available to distribute the applied forces, but the wall thickness acts as its support.

- Parallel Shafts

- Outer diameter and inner diameter is the same throughout the shaft

- This results in the wall thickness being the same throughout the shaft

- The strength and durability is the same throughout the shaft

- This results in the wall thickness being the same throughout the shaft

- Outer diameter and inner diameter is the same throughout the shaft

- Continuous Tapered Shafts

- Outer diameter changes at a set rate (example +0.001”OD/inch of shaft)

- Following the example a 30” shaft would have a difference of 0.030” in diameter from tip to tail

- With a continuous standard inner diameter that 0.030” growth in outer diameter also translates to a 0.015” growth in wall thickness.

- The increasing outer diameter and increasing wall thickness results in a shaft that gets stronger and more supported as you move towards the front of the shaft where the majority of force (impact) is applied.

- With a tapered inner diameter, the wall thickness will stay relatively the same from tip to tail.

- The increasing outer diameter and continuous wall thickness results in a shaft that gets stronger as you move toward the front of the shaft where the majority of force (impact) is applied, but the level of support does not change.

- With a continuous standard inner diameter that 0.030” growth in outer diameter also translates to a 0.015” growth in wall thickness.

- Following the example a 30” shaft would have a difference of 0.030” in diameter from tip to tail

- Outer diameter changes at a set rate (example +0.001”OD/inch of shaft)

*Hybrid tapered shafts tend to utilize a larger parallel shaft at the front and then only taper the rear of the shaft. As such they are a mix of the two evaluations above*

- Barrel Tapered Shafts

- Outer diameter changes at a set rate as you approach the middle of the shaft (example +0.001”OD/inch of shaft)

- Following the example, a 30” shaft would be 0.015” larger diameter in the middle than at the ends

- The middle of the shaft would then see the benefits of that larger diameter, but the ends (the front is our main concern) would not.

- Following the example, a 30” shaft would be 0.015” larger diameter in the middle than at the ends

- Outer diameter changes at a set rate as you approach the middle of the shaft (example +0.001”OD/inch of shaft)

Natural FOC

This is an area that many people tend to overlook, but your shaft tends to make up a majority of the overall weight of your arrow system. Shifting the natural balance point of the shaft itself can lead to substantial changes in your final FOC.

- Parallel Shafts

- The grains per inch (GPI) of the shaft is constant as the outer diameter and inner diameter will remain constant.

- Constant “GPI” value can be listed

- The shafts balance point will be its physical center

- 0 percent FOC

- The grains per inch (GPI) of the shaft is constant as the outer diameter and inner diameter will remain constant.

- Tapered Shafts

- The grains per inch of the shaft is continuously increasing as the outer and/or inner diameter increase from one end of the shaft to the other.

- This is why most tapered shafts do not have a listed “GPI” value

- As the diameter increases the weight will increase

- Continuous outer taper with constant inner diameter will have the largest change in weight from tip to tail

- Shaft will naturally have a balance point forward of center

- Actual balance point depends on rate of taper, but 3-5 percent FOC is common

- Continuous outer and inner taper will still change weight as more carbon is used to create the larger diameter, even though the wall thickness stays the same.

- Shaft will naturally have a balance point forward of center

- Actual balance point depends on rate of taper, but 1-3 percent FOC is common

- Hybrid Tapered shafts can vary widely as it will depend on how much of the shaft is parallel vs tapered. The closer to physical center the parallel portion of shaft gets, the lower the shafts FOC percentage will be

- Continuous outer taper with constant inner diameter will have the largest change in weight from tip to tail

- The grains per inch of the shaft is continuously increasing as the outer and/or inner diameter increase from one end of the shaft to the other.

- Barrel Tapered Shafts

- The grains per inch of the shaft is continuously increasing as you approach the physical center of the shaft.

- Similar to a continuous taper, a “GPI” value will not typically be listed.

- As the diameter increases, weight will increase

- As the diameter change is matched before and after the physical center, the FOC will be 0 percent

- The grains per inch of the shaft is continuously increasing as you approach the physical center of the shaft.

Shaft Flex

There are quite a few factors that impact how much a shaft will flex, but assuming the carbon stays the same, the big factors are the inner and outer diameter of the shaft.

As previously noted, shafts with a larger outer diameter have more surface area to distribute force, which means aside from the durability changes, flex will also change. Larger outer diameter shafts will flex less under the same force than a shaft with a smaller outer diameter—assuming that the wall thickness is the same.

You can see this if you look at two different size shafts with the same spine rating. The smaller shaft will tend to have thicker walls to achieve the same static flex rating. In order to increase the stiffness of any given shaft, the wall thickness will be increased, which will also increase the outer diameter.

When motion comes into play, things are still a bit different though. While not a substantial difference, different diameter shafts with the same static rating will have different levels of flex dynamically (larger outer diameter will tend to act stiffer).

- Parallel Shafts

- Constant inner and outer diameter results in a constant rate of flex throughout the shaft.

- The front, middle and rear of a parallel 300 spine will all flex at the same rate.

- Dynamic reaction of the shaft will be the same regardless of the end cut. The shorter the shaft is cut the stiffer it will act.

- Constant inner and outer diameter results in a constant rate of flex throughout the shaft.

- Tapered Shafts

- Continuous outer taper with a constant inner diameter will have the largest change in the rate of flex

- Each section of shaft will have a different outer diameter and wall thickness resulting in the greatest difference in flex rate

- The tail of the shaft will have the smallest outer diameter and thinnest walls, resulting in more flexibility

- The front of the shaft will have the largest outer diameter and the thickest walls, resulting in less flexibility.

- Continuous outer and inner taper will have a smaller change in the rate of flex

- Each section of shaft will have a different outer diameter, but similar wall thickness resulting in a difference in flex rate

- The tail of the shaft will have the smallest outer diameter, resulting in slightly more flexibility

- The front of the shaft will have the largest outer diameter, resulting in slightly less flexibility

- Hybrid tapered shafts will have an even smaller rate of change in the rate of flex

- The rate of flex throughout the parallel portion of the shaft will be constant as the outer diameter and wall thickness remain constant

- The rate of flex throughout the tapered portion will be changing along with the outer diameter and wall thickness.

- Dynamic reaction of the shaft will change depending on which end of the shaft is cut

- Cutting the rear of the shaft will remove the most flexible portion combined with shortening the shaft length, resulting in significant stiffening

- Cutting the front of the shaft will remove the stiffest portion, but combined with shortening the shaft length will result in minimal increased stiffness.

- Shafts with a continuous outer taper with a constant inner diameter have minimal restrictions for cutting. The constant inner diameter means internal componts/nocks will always fit, but if a sleeve is utilized it will need to be appropriate for the outer diameter of the front of the shaft after being cut.

- Shafts with a continuous outer and inner taper as well as most hybrid tapered shafts will have limitations for cutting either end in order for the components/nocks to properly fit

- Each section of shaft will have a different outer diameter, but similar wall thickness resulting in a difference in flex rate

- Each section of shaft will have a different outer diameter and wall thickness resulting in the greatest difference in flex rate

- Continuous outer taper with a constant inner diameter will have the largest change in the rate of flex

- Barrel Tapered Shafts

- The changing outer diameter and wall thickness will change the rate of flex

- The ends of the shaft will have the smallest outer diameter, resulting in more flexibility

- The middle of the shaft will have the largest outer diameter, resulting in less flexibility

- Dynamic reaction will change as the shaft is cut from either end.

- Cutting either end will be removing the most flexible portion, resulting in increased stiffness.

- Cutting both ends will result in significant stiffening in the reaction of the shaft

- Strategically cutting one end or the other can shift the stiffest portion of shaft from the middle altering the dynamic reaction further.

- Cutting either end will be removing the most flexible portion, resulting in increased stiffness.

- The changing outer diameter and wall thickness will change the rate of flex

Shaft Drag

As you can imagine, the drag created by these different styles of shaft can vary quite a bit. While in flight, there will be various aerodynamic elements at play, but the biggest difference shows during penetration. We already discussed this a bit with the fifth penetration factor (shaft to ferrule ratio) so we should already understand that unnecessary drag can have a large impact, but what about everything behind the ferrule (the shaft)?

When impact occurs, the arrow system is attempting to push and cut its way through whatever material it has encountered. The resistance to the forward motion will result in shaft flex, which will create additional resistance as the shaft pushes against the material being penetrated. The less pressure created in this situation the less drag and the more overall penetration.

Specifically, the less the front of the shaft flexes at impact, the less additional drag created, and the more time for the tail to recover and get in line with the overall direction of force.

We have already covered the differences in how the different shafts flex, so now we are going to focus on the inherent drag of the shaft itself assuming everything stays in proper alignment.

Following what we learned about the fifth penetration factor, the broadhead ferrule should be larger than the component and/or shaft. This means that by the time we reach the shaft, there should be a reduction in pressure from the surrounding material as the shaft should be a smaller diameter. From this point of penetration—and on—it will depend on the type of shaft as to what happens.

- Parallel Shafts

- The outer diameter is constant the full length of the shaft.

- The pressure from surrounding material will be the same, equal for any part of the shaft

- Total drag will be steadily increasing as the shaft continues to penetrate, and the constant pressure is applied against a larger amount of shaft surface area. Once the front of the shaft has passed through, total drag will decrease at the same rate it was gained

- The outer diameter is constant the full length of the shaft.

- Tapered Shafts

- The outer diameter is continuously decreasing as you approach the tail

- The pressure from surrounding material will be greatest at the front of the shaft

- The pressure from surrounding material will be lowest at the tail of the shaft

- Total drag will increase at a much slower rate as the shaft continues to penetrate. Once the front of the shaft has passed through, there will be a sharp decline in drag as the highest pressure section has exited. Drag will continue to drop at an accelerated rate until the shaft has exited completely.

- For hybrid tapered shafts, the shift in drag growth rate will occur once the parallel section of shaft has fully entered as it transitions to the taper. Similarly, the rapid reduction of drag will occur after the parallel section has exited.

- The outer diameter is continuously decreasing as you approach the tail

- Barrel Tapered Shafts

- The outer diameter is increasing as you approach the midpoint and will then begin decreasing

- The pressure from surrounding material will be lowest at the front of the shaft and increasing to its peak at the middle of the shaft

- Total drag will climb rapidly as both the pressure applied and the amount of shaft surface area increases as penetration occurs. The rate of growth will slow once the midpoint has entered. As the front of the shaft exits there will be a slow reduction in drag, but the rate of reduction will improve after the midpoint has exited.

- The outer diameter is increasing as you approach the midpoint and will then begin decreasing

Taking all of this into account, what does it mean for penetration? How can the profile of our chosen shaft impact our expected penetration? Based on the data collected, with all other factors equal, your choice in shaft could mean as much as a 15 percent difference in total penetration.

Looking at all the factors we discussed, parallel shafts are the neutral option. While they do not have many advantages, they also do not have any glaring disadvantages. Plus they are readily available as the predominant style of shaft on the mark.

With parallel shafts as our baseline (0%), a true continuously tapered shaft could see as much as an 8 percent increase in penetration. This increase is primarily due to the naturally stiffer front portion of shaft reducing flex at impact and the reduction of drag from the smaller diameter as you approach the tail. This increased penetration potential combined with the strength and FOC advantage can serve as a great overall improvement if needed.

Going the other way from our baseline parallel shaft, a barrel tapered shaft could see as much as a 7 percent REDUCTION in penetration due to the front portion of shaft being more flexible along with the increased drag from the larger diameter middle of the shaft. Just like with the shaft to ferrule ratio, this just goes to show how seemingly small things can create a significant difference when push comes to shove.

Get to know the authors!

Dr. Ed Ashby

Dr. Ed Ashby, a legend in the archery hunting community, dedicated more than 27 years to the study of arrow performance and broadhead lethality. His involvement in the historic Natal Study helped validate just how lethal archery equipment could be on all sized big game animals and was the main reason that bowhunting was ever legalized in South Africa.

Rob Hummel

With a background in fabrication and engineering, the current standard being pushed by the industry didn’t feel right when Rob first entered the world of archery. Fortunately, after being directed to some of the reports from Dr. Ed Ashby’s field research it all began to align with the mechanics he already understood. Over the last decade, Rob has continued pushing to bring consistent lethality to the forefront of the archery industry.

Todd Smith

For over 40-years, his passion for bowhunting and thirst for knowledge and understanding have driven Todd to learn everything he could about arrows, broadheads, and arrow lethality. Todd is an author, public speaker, and has helped to educate tens of thousands of bowhunters on how to set themselves up for bowhunting successes by using proven – lethal – arrow and broadhead set-ups.

What’s the Ashby Bowhunting Foundation all about?

The Ashby Bowhunting Foundation is dedicated to continuing Dr. Ed Ashby’s research and to ensuring that bowhunters everywhere will have free access to information that will help them build extremely lethal and reliable arrow and broadhead setups for all species of big game. The foundation was started in 2017 to continue the work of Dr. Ed Ashby that has benefited bowhunters worldwide for decades. The Foundation’s goal is to provide information to achieve the highest possible success rate and reduce the wound/non-recovery rate of big game to the lowest level possible. Through a program of continuing research, the Foundation seeks to find the most lethal arrow setups, taking into account all possible hits under real hunting conditions, controlled testing and using freshly culled animals. The results of this testing is always made available to the global bowhunting community free of cost, utilizing multi-media outlets for information and test results. The Ashby Bowhunting Foundation is excited for this opportunity to partner with DSC and to share these articles with all DSC members so they can make informed decisions of whether to change to arrow and broadhead combinations that will increase their odds of bowhunting success under all situations and conditions. For more information please visit: https://www.biggame.org/ashby-bowhunting-foundation