Rethinking Arrow and Broadhead Performance

A NEW Series of Bowhunting Articles by the Ashby Bowhunting Foundation

Article 2: Factor 1 – Structural Integrity

Would you like to hunt with arrows and broadheads that give you pass-throughs on big game shot after shot? Would you like to have complete confidence in your arrows and broadheads to give you lethal penetration and reliable kills even if you hit bone? Of course, you would! Every serious bowhunter wants that kind of performance from their setup.

After extensive testing, Dr. Ed Ashby identified twelve specific arrow penetration enhancement factors. He then ranked them in order of importance so that bowhunters would know what the most important of the factors were and by ranking them, it would give bowhunters a roadmap of where to start and what to build into their arrow and broadhead setups to make them the most reliably lethal setups possible.

To optimize your arrow and broadhead builds, it is recommended that you incorporate as many of the 12 Penetration Enhancement Factors as possible. The first, and most important of the factors, STRUCTURAL INTEGRITY, is the topic we are covering in this article.

“If your arrow or broadhead fails, penetration stops.” Dr. Ed Ashby

The structural integrity—strength and toughness—of an arrow and broadhead combination, or “system” is one of the few topics in archery that the vast majority of bowhunters seem to actually agree on. Ask anyone if they would prefer hunting with an arrow and broadhead that can withstand hard impacts, and you will be hard pressed to find someone that disagrees. Why then do so many people still deal with the heartache of walking up to where an animal once stood, to find their arrow broken off, realizing that they didn’t achieve nearly as much penetration as they expected?

The sad truth is that a majority of bowhunters out there believe that “It’s just what it is.” They think that no arrow can withstand hard impacts. This belief then leads to the feeling that the fault lies 100 percent on their shot placement or just plain old bad luck. “If only I had made a better shot.” “If only the animal hadn’t turned.” “If only the animal hadn’t ducked.” Sound familiar? The issue with this is that even a less than perfect shot, if in line with the vitals, will be lethal if there is enough penetration and the number one way to improve the likelihood of achieving a lethal level of penetration is to make sure that everything stays undamaged and in one piece during the penetration process. This truly is achievable with a well built system, even if it goes against what the majority of hunters have seen in the field when they’re using the current industry standard systems.

Now, every hunter should try to be as prepared as possible and always try to make the best shot they can in every bowhunting situation. It should be assumed that any respectable hunter is making their best effort to wait for and take only a clean shot, but some things are simply out of your hands. Once that arrow leaves the string, the only control you have is with the equipment that you selected for the job. Like any other system, your complete arrow system should be built with a safety factor in mind. We shouldn’t be selecting shafts, components, and broadheads for when things go perfectly to plan; we need to think about all of those situations that are out of our control and plan ahead in an effort to ensure success.

So why exactly do we need to put this level of effort into simply building an arrow? Why does it really matter in regard to our expected level of penetration? In the end, penetration is about one key element: preserving your energy and thus your force. Every single factor that we will be discussing throughout these articles can be traced back to this key concept. The better your arrow system retains the energy transferred from your bow, the better your penetration will be and breaking a broadhead, component, or shaft is the largest waste of energy you can have.

When one of these pieces break, it is due to an excess amount of energy being directed out of line with the arrow system. This means that all of the energy involved in breaking that piece is no longer available to continue moving forward, the broken piece creates significant additional resistance, and in the majority of cases, all penetration comes to a halt. Avoiding this waste of potential has the largest impact overall. Flight can be perfect, the broadhead can be efficient, you can have plenty of mass, but if some piece of the system fails at impact then it’s all for naught.

So how exactly do we go about selecting all of these different pieces, or elements of our arrow builds? How can you know what makes one thing better than the next without spending countless hours, days, and years testing everything on the market? Luckily, that testing has been ongoing for decades, and there are some key elements that you can evaluate when deciding on your next build.

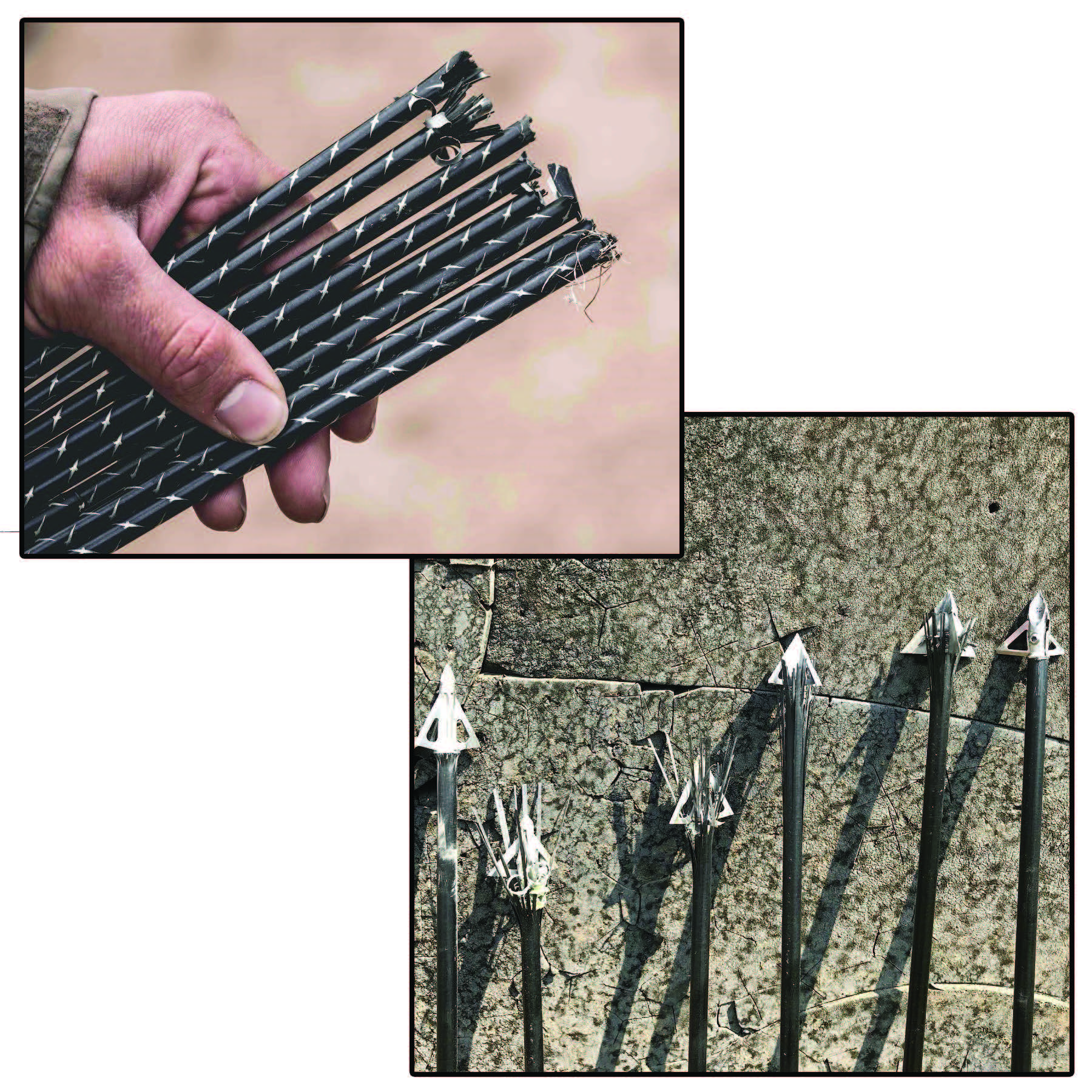

- THE BROADHEAD

The first element to consider is the broadhead. Not only is it literally the leading edge of your system, but how it reacts to impact will directly affect the rest of the system.

- Tip Style: The style of the tip will tell you how likely it is to bend or curl. Something like a needle point has less support and is more likely to sustain damage than something along the lines of a tanto point.

- Blade Thickness & Ferrule Design: The overall material thickness and ferrule design will help you understand how rigid the blade is, as well as how much support it has. Thicker blades will be more rigid, and the longer the ferrule continues toward the tip of the blade, the more support it will offer.

- Bevel Angle: The bevel angle or grind on the cutting edge will help you understand how much support that edge has. The lower the grind angle the sharper the edge can be, but there will be less material, and thus less support increasing the likelihood that damage will be sustained. While minor chipping likely will not lead to a complete structural failure, larger chips can lead to unexpected pressure being applied and lead to more catastrophic results.

All of these elements play into what you can expect to happen when impact occurs. Even if the broadhead doesn’t completely fail, any bending that occurs will cause the arrows path to deviate and misalign the predominant force with the rest of the system, placing greater stress on those other components.

2. THE COMPONENT

Next in line is the component. This could be an insert, outsert, half-out, or a combination depending on the brand you are looking at. Not only is this the attachment point for both the broadhead and the shaft, but it also has the potential to amplify or reduce the forces applied to the shaft at impact.

- Leverage Against the Shaft: The distance from the end of the carbon to the ferrule of the broadhead determines how much additional leverage the broadhead will have to apply any forces against the shaft. The greater this distance, the more leverage, and the more force the shaft must be able to handle. Most full outserts have nearly an inch between the end of the carbon and the start of the broadhead ferrule. This is a significant increase in leverage compared to most inserts that are only around a sixteenth of an inch, resulting in the forces applied to the shaft being drastically different.

- Internal Shaft Support: On the flip side, the amount of component inside the shaft will indicate how much support is being provided. A longer internal post will provide greater support and help dissipate the applied forces before they reach the unsupported portion of the shaft. This transition from supported to unsupported carbon is one of the most common break points for an arrow and the amount of support provided by the component plays a huge role.

- External Shaft Support: Externally, something to consider is a footer. Depending on brand this could be referred to as a sleeve or an outsert as well. The footer works in tandem with an existing internal component and its purpose is to protect the leading edge of the carbon and prevent it from swelling/expanding at impact. Lack of this type of reinforcement can lead to the broadhead and component being pushed further into the shaft, pushing the splintering carbon out in all directions, or it could allow the component to rip through the side of an arrow.

Now before moving on to the shaft, I want to quickly mention materials. The materials utilized in both the broadhead and the component can play a big role in their overall structural integrity, but the design can have a larger impact overall. The best, most expensive material available cannot make up for a poor design, but a truly great design can significantly alter how a less than ideal material performs. So while it is definitely something to look at and evaluate, do not discount what appears to be a great design simply because it isn’t the latest and greatest material on the market.

3. THE SHAFT

The last portion of your system will be the shaft itself. While any shafts durability can be improved with the right choice of broadhead and component there are still a handful of factors that can be used to evaluate the inherent strengths and weaknesses between various arrow shafts.

- GPI: The simplest tool for a quick evaluation is a shaft grain per inch or GPI. Looking at the spine rating vs the grains per inch (GPI) of the shaft can give you a lot of useful information when making comparisons. Typically, the stiffer the spine, the more carbon will be used, which will increase the GPI of the shaft. The issue is that some manufacturers will alter a shafts spine in other ways and some of those ways are not quite as durable as others. If you notice that a shafts GPI really doesn’t increase as much as expected (or in some cases actually stays the same) when moving from one spine to the next stiffer then there is a good chance that different modulus carbon is being used. This can allow the shaft to be more rigid without actually using more carbon. There are definite benefits to this, but brittleness can be a concern. In general, when looking at shafts of the same spine, the one with a higher GPI will tend to be more durable overall.

- Diameter & Wall Thickness: GPI can be a good rough gauge, but other factors can play into exactly how durable a shaft is. Similar to tubing, the outer diameter and wall thickness of the shaft play a large role in how much force it can actually withstand. Increasing wall thickness does lead to a more durable shaft, but weight can add up quickly and that can outweigh the durability increase. Increasing the outer diameter while maintaining a similar wall thickness will actually yield a stronger shaft overall. Make sure to keep this in mind when looking at the various shaft options out on the market today. A standard diameter shaft may have a slightly lower GPI (thinner walls) than a micro diameter shaft (thicker walls), but realistically the standard diameter shaft will be able to withstand greater force due to its larger diameter. The reason for this is that when force is applied to a tube it gets distributed around the surface of the tube. The larger the diameter, the more spread out the force is meaning that a greater overall force can be applied before failure occurs.

- Shaft Profile: While not extremely common in the current market, if you are looking for an additional leg up in the durability department the shaft profile is something to consider. The majority of shafts on the market have a parallel design meaning that both the inside and outside diameters are continuous and thus the wall thickness and spine are consistent as well. This isn’t a concern in most cases, but a shaft with a tapered design does have some advantages. A shaft with a tapered profile takes advantage of the diameter and wall thickness benefits we already mentioned. By having a larger diameter and thicker walls at the front of the shaft tapering down to a smaller tail, it will effectively be reinforcing the region where most failures occur without unnecessarily adding weight throughout the entire shaft. Tapered shafts, by design increase your FOC, they’re stronger at the front to reduce arrow failure, and they are more stiff at the front too so they penetrate more efficiently by reducing the sideways frictions of impact paradox or impact flex.

If your broadhead fails on impact penetration stops or is greatly reduced.

All of these seemingly small factors play into how your system will handle a hard impact if/when it occurs. The most important thing to remember with all of this is that every component of your arrow build is responsible to do its part and is expected to remain intact while penetrating your animals. All of these components must work together to provide you the highest likelihood of remaining intact while pushing your broadhead in one side and out the other. Every individual component may not be “perfect”, but when you take the time to select only solid components that have a track record of being tough – you’ll end up with an arrow build that should be rock-solid in all situations and under all circumstances.

In the end YOU need to be confident that your system will be able to handle whatever challenges it encounters. When you’re confident, all of those “What if?” questions disappear, and you can simply focus on the shot. When that happens, you may be pleasantly surprised at how lethal your arrow build is, even when your situation does not go according to plan.

Get to know the authors!

[author] [author_image timthumb=’on’]https://www.biggame.org/wp-content/uploads/2021/06/dr-ed-ashby-bio-pic-002.jpg[/author_image] [author_info]Dr. Ed Ashby

Dr. Ed Ashby, a legend in the archery hunting community, dedicated more than 27 years to the study of arrow performance and broadhead lethality. His involvement in the historic Natal Study helped validate just how lethal archery equipment could be on all sized big game animals and was the main reason that bowhunting was ever legalized in South Africa. [/author_info] [/author]

[author] [author_image timthumb=’on’]https://www.biggame.org/wp-content/uploads/2021/06/rob-hummel-bio-pic-002.jpg[/author_image] [author_info] Rob Hummel

With a background in fabrication and engineering, the current standard being pushed by the industry didn’t feel right when Rob first entered the world of archery. Fortunately, after being directed to some of the reports from Dr. Ed Ashby’s field research it all began to align with the mechanics he already understood. Over the last decade, Rob has continued pushing to bring consistent lethality to the forefront of the archery industry. [/author_info] [/author]

[author] [author_image timthumb=’on’]https://www.biggame.org/wp-content/uploads/2021/06/todd-michael-smith-bio-pic-002.jpg[/author_image] [author_info] Todd Smith

For over 40-years, his passion for bowhunting and thirst for knowledge and understanding have driven Todd to learn everything he could about arrows, broadheads, and arrow lethality. Todd is an author, public speaker, and has helped to educate tens of thousands of bowhunters on how to set themselves up for bowhunting successes by using proven – lethal – arrow and broadhead set-ups.[/author_info] [/author]

[box] What’s the Ashby Bowhunting Foundation all about?

The Ashby Bowhunting Foundation is dedicated to continuing Dr. Ed Ashby’s research and to ensuring that bowhunters everywhere will have free access to information that will help them build extremely lethal and reliable arrow and broadhead setups for all species of big game. The foundation was started in 2017 to continue the work of Dr. Ed Ashby that has benefited bowhunters worldwide for decades. The Foundation’s goal is to provide information to achieve the highest possible success rate and reduce the wound/non-recovery rate of big game to the lowest level possible. Through a program of continuing research, the Foundation seeks to find the most lethal arrow setups, taking into account all possible hits under real hunting conditions, controlled testing and using freshly culled animals. The results of this testing is always made available to the global bowhunting community free of cost, utilizing multi-media outlets for information and test results. The Ashby Bowhunting Foundation is excited for this opportunity to partner with DSC and to share these articles with all DSC members so they can make informed decisions of whether to change to arrow and broadhead combinations that will increase their odds of bowhunting success under all situations and conditions. For more information please visit: https://www.biggame.org/ashby-bowhunting-foundation [/box]